Product Features

Function: Our cable could use for charging the device, sync data from 2 different devices, connect video signal from output devices to the input devices, and connect the device for transfer data purposes.

Type C, as a newly released terminal, not only has more pin then old version micro, mini, type A, and type B terminal but also has a new feature that could plugin without considering the front or back. Type C terminal has the same design on both sides, so it has more lifetime compare with old version one because it will not hurt by unproperly plugin. Also, it could save time for the user to check the front or back side before plugin.

People are using USB cable every single day, so a durable lifetime is customers' first requirement. Our connector used on our data cable is purchase from a famous supplier in China. They have many years' experience in connector production. We could choose different quality connectors for customers according to their requirements.

Product Specification

Material

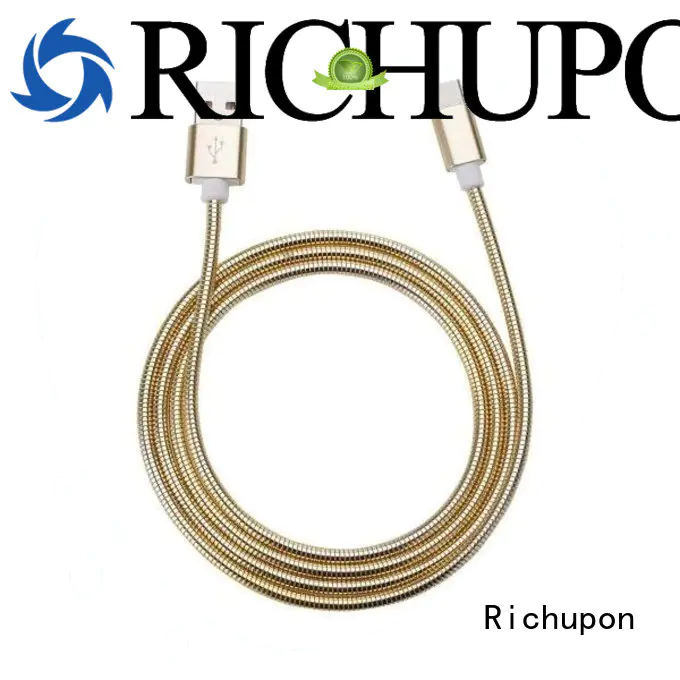

Some decades ago, PVC was a popular material for cable jackets, but PVC is not good for the environment. Nowadays, most of the large manufacturers are using TPE instead of a PVC jacket for cable since TPE is an environmental-friendly material. We also have nylon, fishnet, leather, metal spring, PU, Denim for you choose, or we can develop new material with your request.

For the shells, we have three materials to make our shells. One is an aluminum alloy, one is zinc alloy, and another one is plastic molding. If you have any other requests about the shell, we will develop new material to satisfy your needs.

USB generation

Different USB generation has different standard requirement for cable manufacturer. For the USB 2.0, cable must be pass through 480 Mb/s data, and 5 Gb/s for USB 3.0, 3.1 gen 1, 3.2 gen 1, and 10 Gb/s for USB 3.1 gen2, USB 3.2 gen2. Backwards compatible.

Welding

Welding technology is one of our significant advantages. We could use tinplate on welding to make sure the connector and wire are welding properly. Could afford at least 10 thousand times mating cycles. Also, make sure there do not have any short between each wire. We can use different version's tinplate according to the different design.

Fast charge

We have long term cooperation with chip suppliers. Our top engineer will develop the cable that satisfies different fast charge agreement. Make sure our customers could get the most advanced cable with the newest fast charge agreement.

Tooling

We have a professional engineering team to ensure our product has high accuracy by choosing better mold, training labor, and develop the technology. We will satisfy our customers' requests about the specification.

Color

Our company supports OEM/ODM service, and we support all RGB colors for cable shell or jacket.

Length

We can make different length cables that satisfy our customers' different needs.

Detailed Product Description

| Connectors | Type C / Type A / Tin-plated / Gold-plated | Material | TPE / PVC / Nylon / Fishnet / Metal Spring / Customized |

| Length | 1m / 2m / 3m / 3ft / 6ft / 10ft / Customized | Color | Red / Pink / White / Black / Gold / Green / Customized |

| USB Specification | 2.0 / 3.0 / 3.1 / 3.2 / 3.1gen1 / 3.1gen2 / 3.2gen1 / 3.2gen2 | Fast Charge | PD / QC / VOOC / FCP / SCP / PE |

| Reliability Test | Plug Force Test / Plug TIme Test / Swing Test / Salt Spray Test | Backwards Compatible | Yes |

| Bandwidth | 480Mbps / 5Gbps / 10Gbps | Shell | Aluminum Alloy / Zinc Alloy / Plastic Molding |

USB 2.0 Type C to Type A Data Charging Cable 480Mb/s Metal Spring.

About Us

OEM/ODM

We have a professional research and development team to support our customer's OEM and ODM requests. For OEM service, we could print your logo at our existing products. Also, we could use your design or help you design the package. For the ODM service, our professional engineer could develop a new product to satisfy your request.

Quality check

We have a group of quality check team to ensure we do not support any fail product to our customer. Our production line has at least 4 check process before the final check. First is the continuity test after the tin process. The second is after molding. The third is after setting the shell. And final check before delivery.

Reliability test

Our quality check group is also responsible for make sure our product will pass the reliability test. Our basic reliability test is 10000 times mating cycles test, 10KG plug force test, Swing test, and Salt Spray Test. Our reliability test standard could adjust according to the customer request. Also, we can add more test if the customer needs.

Supplier

We have a very high standard for selecting our supplier. Our expert purchase group aims to choose high performance cost ratio supplier for our customer's materials. We will make sure our customers will not waste money on unnecessary costs. We could ask our supplier to support the cable that satisfies the UL and RoHS standards.

Warranty

We support one year warranty on our product.

Payment period

We need a 30-50% deposit in advance before our production. The remaining part needs to pay before shipment.

Why choose us

Richupon has more than 19 years of experience in cable manufacturing. Our primary goal is to support high-quality products to our customers. We only cooperate with high request customers. Most of our customers are not satisfied with their previous supplier's quality. After they see our quality, they will have long term cooperation with us.

Service hour

Our phone number is 24 hours available for call in. Email and message usually reply in 10 hours.

Copyright © 2025 Richupon Electronics Shenzhen Co. Ltd. | All Rights Reserved